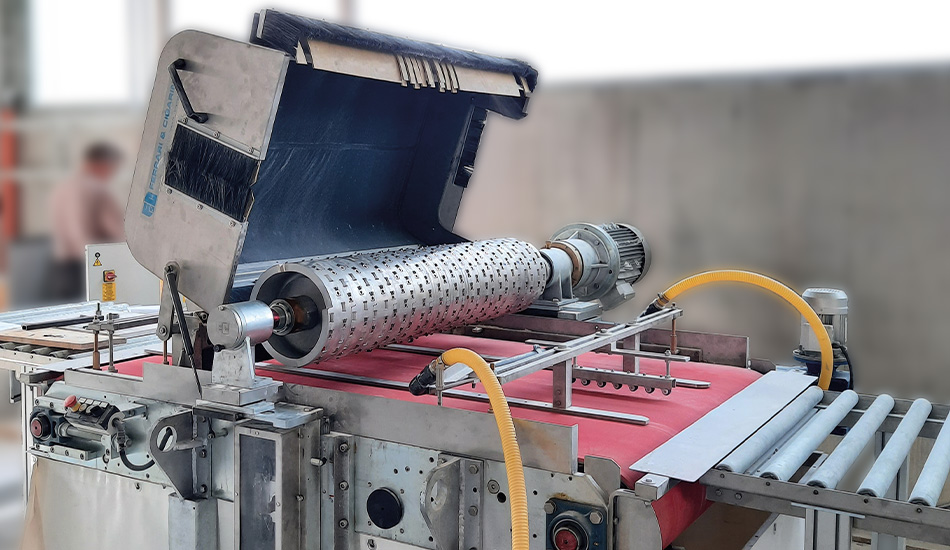

Scratching machine with horizontal shaft for tiles and slabs

Groove 600 and 1200 are machines for scratching finishes on slabs and tiles. They are born from the collaboration between Lupato Meccanica and Ferrari & Cigarini. They have been developed to produce more than 60 different finishes with high productivity and low production costs.

Thanks to their compact shape, they are suitable for being integrated into existing production lines. They have an horizontal shaft on which a specially developed tool is installed, controlled on 4 axis.

ROKER tool

The Groove 600 and 1200 are fitted respectively with a 700 mm and a 1,300 mm Roker tool with inserts spaced every 2.5 mm. By removing the inserts and adjusting the parameters of the 4 machining axes, it is possible to vary both the finish.

The bits, as designed, allow high material removal, productivity and durability.

By turning the bits, all their vertexs can be used, multiplying the tool life by 3 times.

Strengths

| GROOVE 600 | GROOVE 1200 | ||

| Slabs width | Up to a maximum of 650 mm | Up to a maximum of 1,250 mm | |

| Rotation speed | From 600 to 2,300 RPM | Independent adjustment of these parameters makes it possible to achieve over 60 finishes. | |

| Belt speed | up to 14 m/min. | ||

| Translation | The tool can translate longitudinally along its axis of rotation with adjustable speed.. | ||

| Tilting | The roller’s axis of rotation can be tilted up to 15° with respect to the belt’s feed direction. | ||

Groove can produce more than 60 different finishes by using one tool

CONTACT US

For any further information about our tools, where to find them and our services, including support, please contact us at any time by filling in this form and sending it to us.